Zoomlion Deployed the Customized Weighing Control Solution Designed by General Measure for 10 Years

Published: 2019-05-10 Article source: This station

General Measure was requested by Zoomlion to design a new weighing control solution for its concrete batching plants in 2008. And this solution is still working well in thousands of Concrete Batching Plants in China.

|

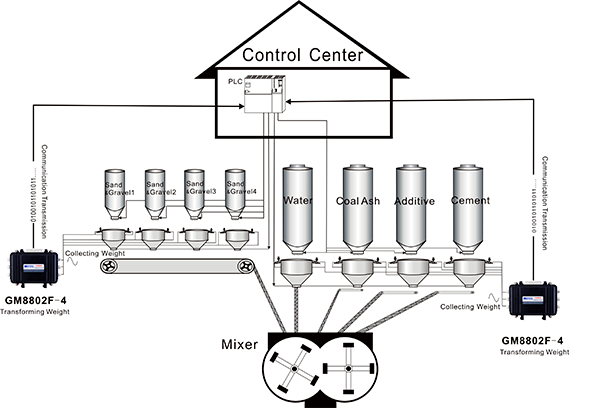

General Measure offers a solution of weights transition directly from the concrete batching sites by field mounting transmitter GM8802-4: 1 indicator controls 4 batching scales simultaneously.

Features

High Efficiency – with 4 independent channels of A/D bundled together.

Safe Budgets – need less weighing transmitters at site and reduce the wiring cost.

User Friendly – field mounting.

Robust Application – IP65 allows it performance in harsh industrial environments.

|

Background and Problems:

After 2000, plenty of concrete batching plants were built up since China has developed infrastructure construction. There were 2 main weighing control solution applied widely. The first way is to deploy 1 weighing indicator for 4 batching scales but point for point. Thus the efficiency and accuracy is low. The second way is to use 4 indicators for 4 batching scales. The efficiency has been increased a bit, but the cost has also been raised due to more usage of indicator and load cell. Under this circumstance, Zoomlion cooperated with General Measure and asked for the customizing and optimizing weighing control solution.

Solution:

Before 2008, Zoomlion had applied the second batching method and only requested us to design a weighing indicator for displaying data. That was the reason of GM8891 launched. At that time, there were thousands of GM8891 running in the concrete batching plants with pretty low repair rate every year.

During the field research, we found the second batching method has the time-delayed problem – when transforming the weights, every serial port need to be checked. If they want to solve this problem based on original solution, they can use the multi-serial port card that is pricy. So, in 2008 Zoomlion found us again for solving this low efficiency and high cost problem.

After field research and analysis, General Measure’s R&D dept. invented GM8802F, a field mounting weighing transmitter, to launch a new solution which combined the previous approaches to realize the function of 1 indicator controlling 4 batching scale simultaneously and collecting 4 batching scale’s data at the same time before data packet packed and transited. This new weighing control solution not only enhances the batching efficiency and but also safes the cost for purchasing more indicators and field wiring.

Zoomlion was very happy with this customized solution. After one and half year’s tests, this weighing control solution was officially deployed in Zoomlion’s concrete batching plants. Until now, it is still the main method for concrete batching control.