New Arrival: AF-100K Gross Weigher from General Measure

Published: 2025-07-09 Article source:

|

1. Brief Overview

AF-100K is a high-speed, high-accuracy packing scale that directly weighs materials inside the packaging bag without the need for a weighing hopper. It features a wide weighing range and user-friendly operation, and is widely used in industries such as grain processing, feed production, chemical raw material packaging, and pharmaceutical dosing. It is especially suitable for free-flowing granular materials.

|

2. Product Description

2.1 Structural Design

The AF-100K consists of a servo motor-controlled feeding mechanism, a pneumatic bag-clamping system, a high-precision triple load cells weighing structure, and a sealed control box.

|

|

The machine is made of S304 stainless steel, and the control box is sealed for dust-proof and moisture-resistant, providing stable operation even in harsh environments.

For weighing accuracy, the machine is equipped with three high-precision load cells, which greatly reduce errors caused by external interference. Compared to single or dual load cell structures, the triple load cells setup significantly improves both weighing speed and accuracy.

To meet the needs of various installation environments, the equipment features a compact dimensions of 685×588×713mm (L×W×H). It is not only save space but also facilitate easier installation and maintenance.

2.2 Working Principle

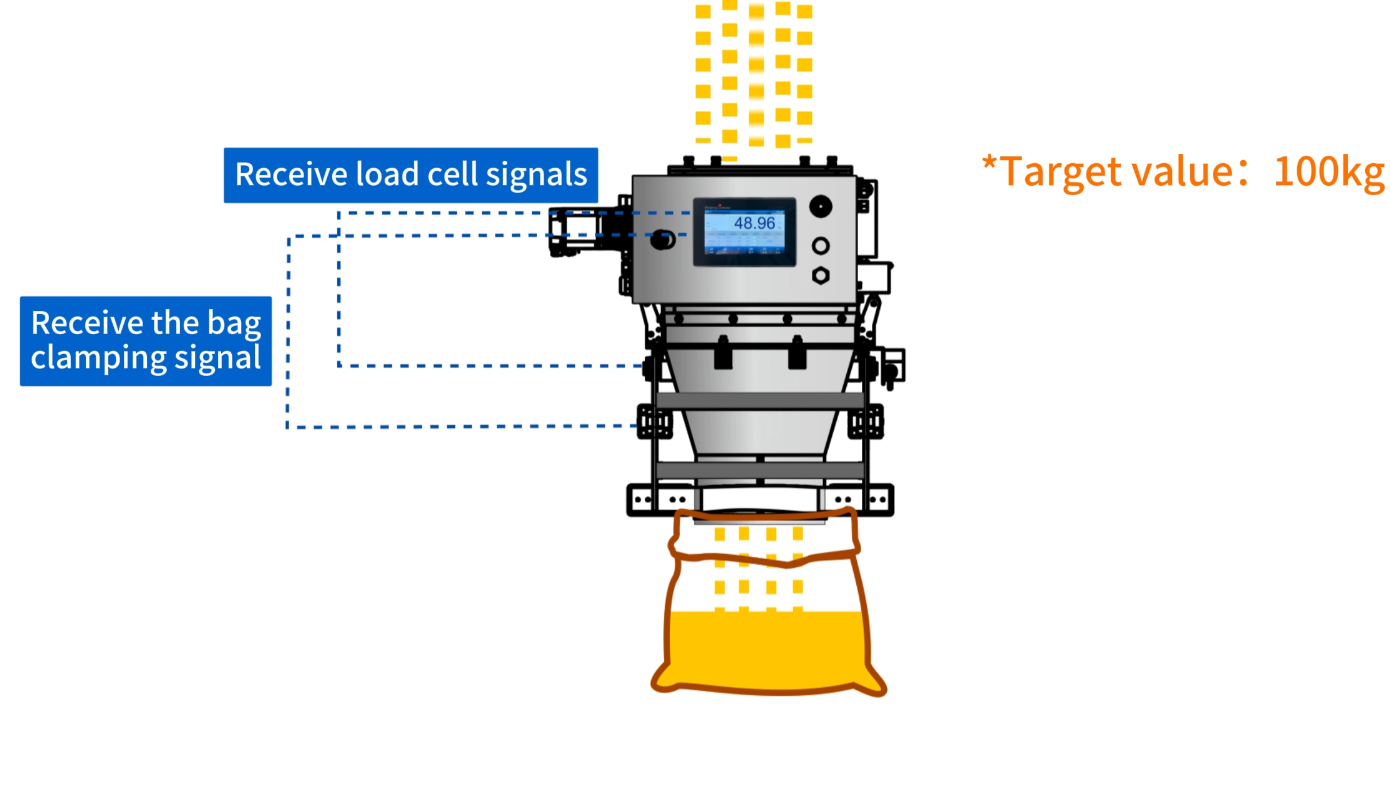

Once the system receives a bag-clamping signal, the material is discharged directly into the bag via the feeding mechanism. The weighing indicator receives signals from the load cell and, based on pre-set parameters, the servo motor executes feeding control. (fast, medium, slow)

|

When the target weight is reached, and the weight reading is stabilized, releases the bag. One pack is complete. The system then waits for the next bag-clamping signal to begin the following cycle.

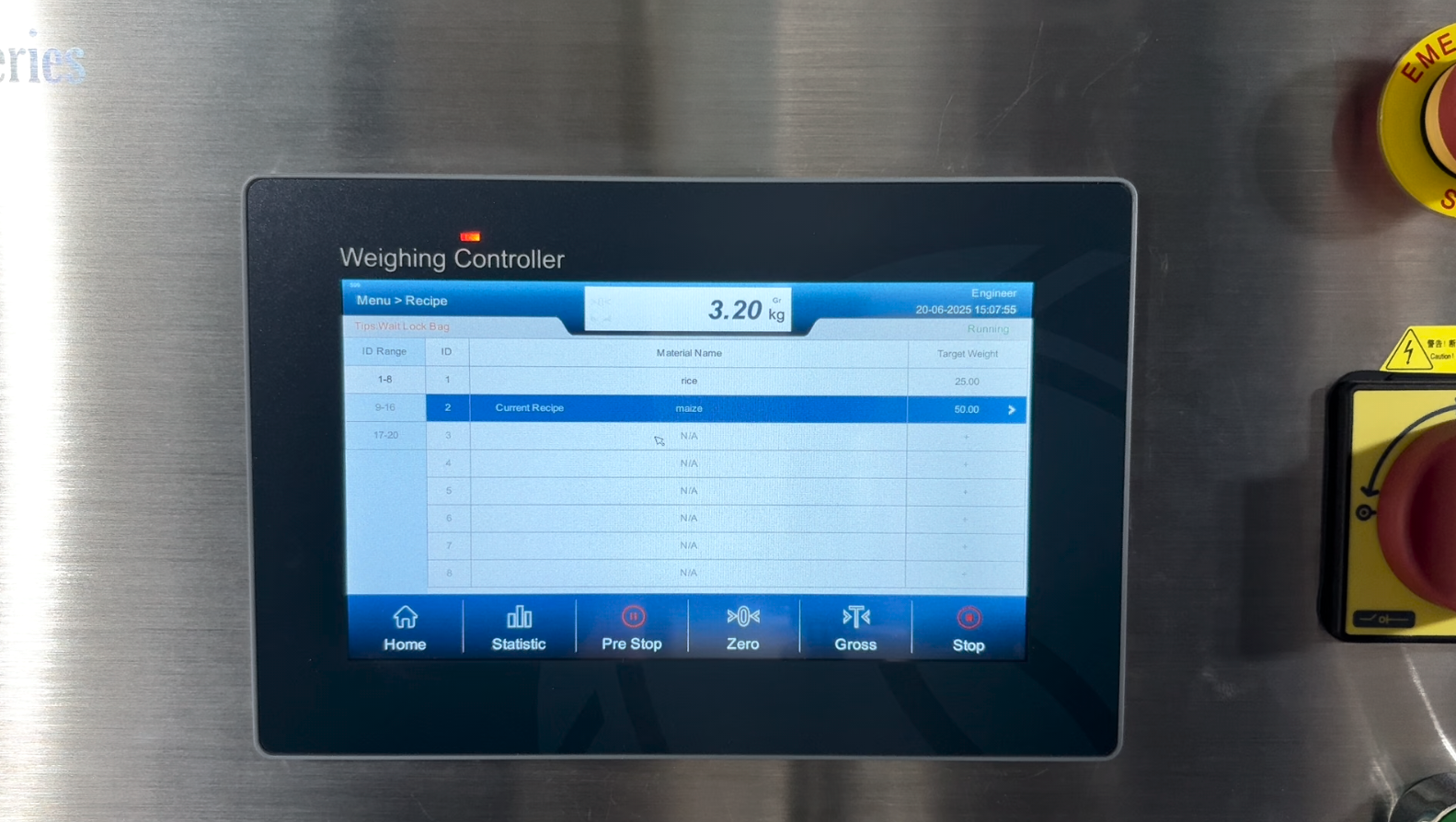

The AF-100K has 20 formula presets. Each with independently configurable parameters, allowing for quick switching, which save the time. Historical packaging data, recipe totals, and cumulative production data are automatically recorded and can be exported via USB drive for analysis.

|

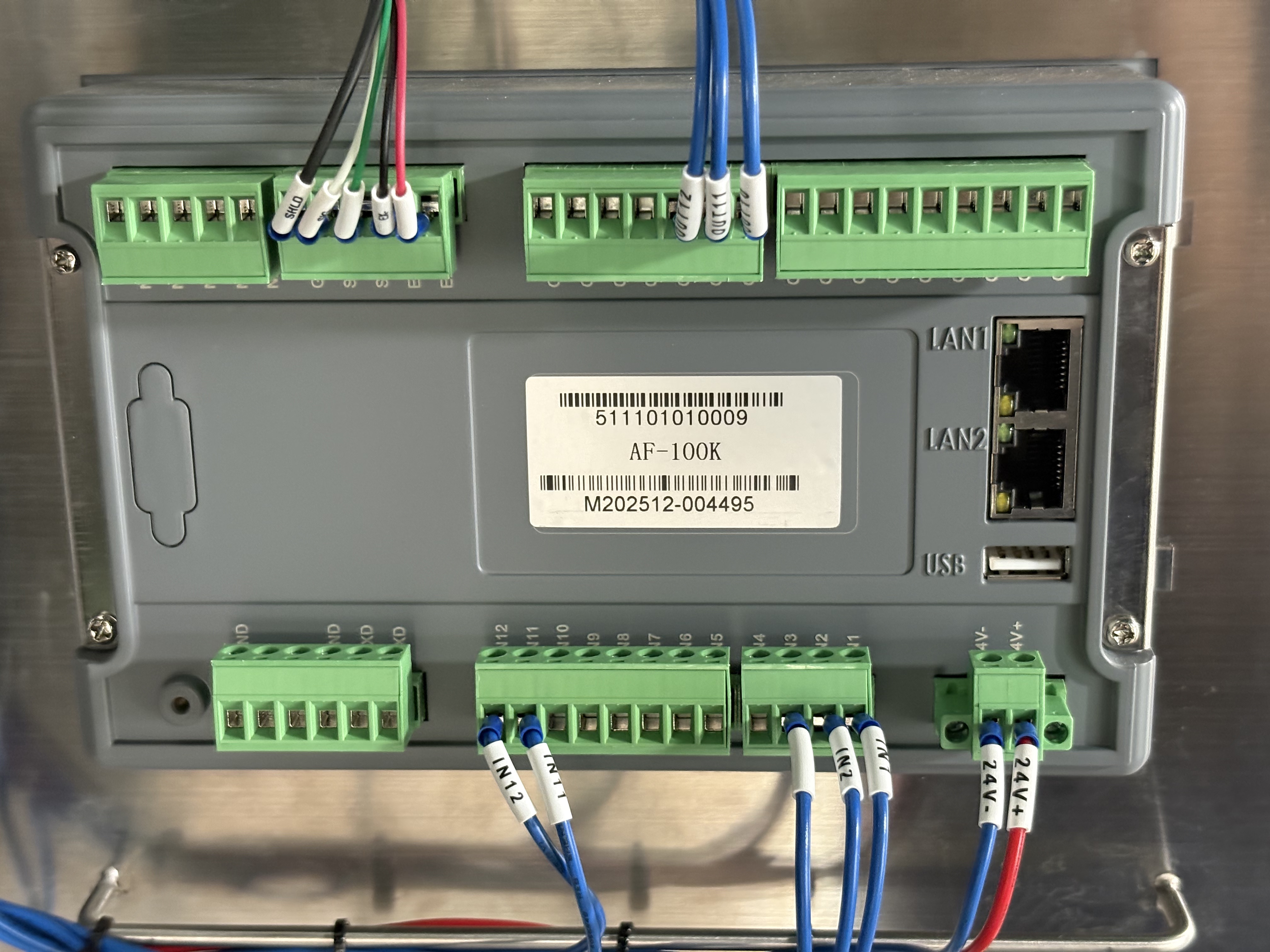

For peripherals and communication systems, the equipment provides 12 inputs and 16 outputs, as well as dual serial ports and an Modbus TCP port, enabling seamless integration with conveyors, sewing machines, printers, PLCs, upper computer and so on.

|

2.3 Key Specifications

Power Supply: Standard AV 220V, 1KW power consumption

Pneumatic Requirement: 0.4–0.8 MPa compressed air for the bag-clamping mechanism

Working Environment: Temperature 0–40°C, humidity up to 90% (non-condensing)

Weighing Range: 5–100kg

Packing Speed: ≥500 bags/hour

Accuracy: ±25g

3. Conclusion

The General Measure AF-100K Gross Weigher stands out as a robust, high-performance solution tailored for modern packaging needs. Its durable construction ensures long-term stability and reliable operation even in demanding environments. With high-speed weighing capabilities, it significantly boosts packaging efficiency, while its exceptional accuracy guarantees consistent and precise results. Whether applied in grain processing, feed production, or other bulk material industries, the AF-100K offers the perfect balance of strength, speed, and precision, making it an ideal choice for businesses aiming to enhance productivity and maintain high-quality standards.