Empowering Smart Farming: General Measure Weighing Solutions in Muyuan’s Integrated Pig Farming Operations

Published: 2025-06-15 Article source:

Muyuan Group stands as a leader in China's livestock industry, recognized for its fully integrated pig farming model and large-scale, intelligent operations. With a firm commitment to efficiency, traceability, and digitalization, Muyuan has been rapidly transforming its production processes to align with smart agriculture and Industry 4.0 standards.

Over the past five years, Muyuan has been partnering with General Measure (GM) to deploy advanced weighing systems across various stages of pig farming and processing. The partnership has seen sustained growth in demand, with projected usage of General Measure products surpassing 10,000 units in 2025 alone. GM's reliable and precise weighing solutions have become an essential component of Muyuan's smart production chain — helping improve operational efficiency, reduce waste, and support real-time data acquisition for digital transformation.

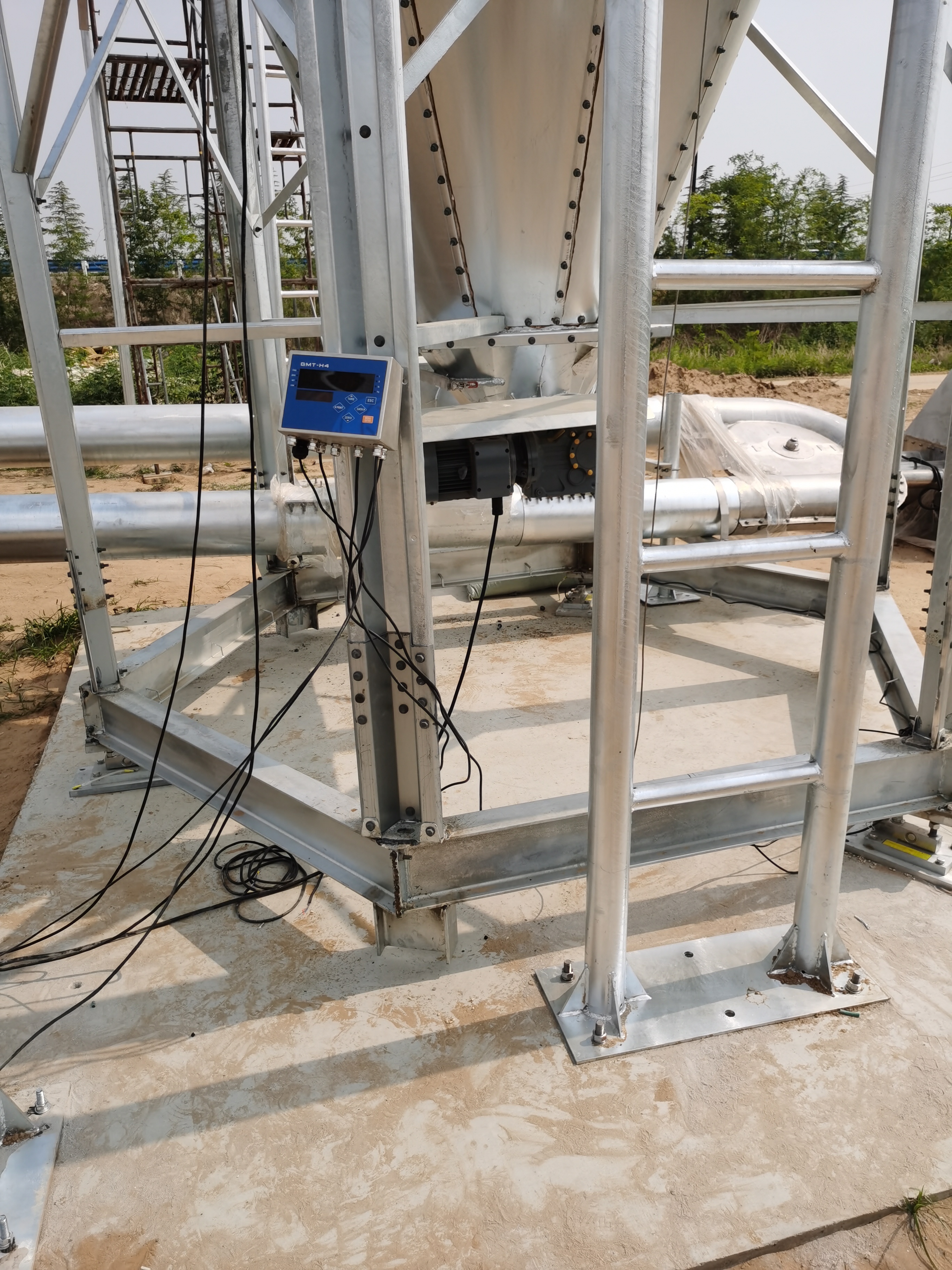

1. Silo Weighing: Ensuring Accurate and Efficient Feeding in Pig Farms

In pig farming, feed management is critical to animal health, growth, and cost control. Muyuan has deployed GM weighing systems in its feed towers to enable real-time monitoring and accurate feed usage tracking. These systems feature a range of General Measure weighing instruments and load cells, including GMT-P1, GMT-H1, GMT-X4 and GMT-H4.

- GMT-P1: Compact, Stabe, and OIML Certified

The GMT-P1 weighing indicator is designed for high-precision weight transmitting. With its compact design, OIML R76 certification, and superior stability, the GMT-P1 is widely used in silo weighing applications to deliver accurate and reliable real-time weight data for Muyuan. With an IP65 protection rating, it performs reliably in outdoor environments. This ensures optimal feed distribution and inventory management across large-scale farms. GMT-P1 becomes the most commonly used weighing indicator for Muyuan's silo weighing.

- GMT-H1: Inteligent In/Out Materias Management with Mobie App Integration

For dynamic feed monitoring, Muyuan utilizes the GMT-H1 indicator — a smart solution featuring a dedicated mobile app that provides instant visibility into feed tower inventory. It enables efficient in/out material tracking, remote alarm setting for feed level thresholds, and real-time data access via mobile devices. This supports timely replenishment, reduces manual inspection, and improves overall feeding accuracy.

To simplify installation and boost scalability, Muyuan has implemented the GMT-X4 (rail-mount) and GMT-H4(wall-mount), the four-channel weighing indicators capable of directly connecting to four load cells without the need for a traditional junction box. This significantly reduces wiring complexity and setup time. Moreover, the GMT-H4 includes intelligent fault diagnostics that automatically identify and localize load cell or signal issues, minimizing downtime and maintenance efforts.

|

|

|

|

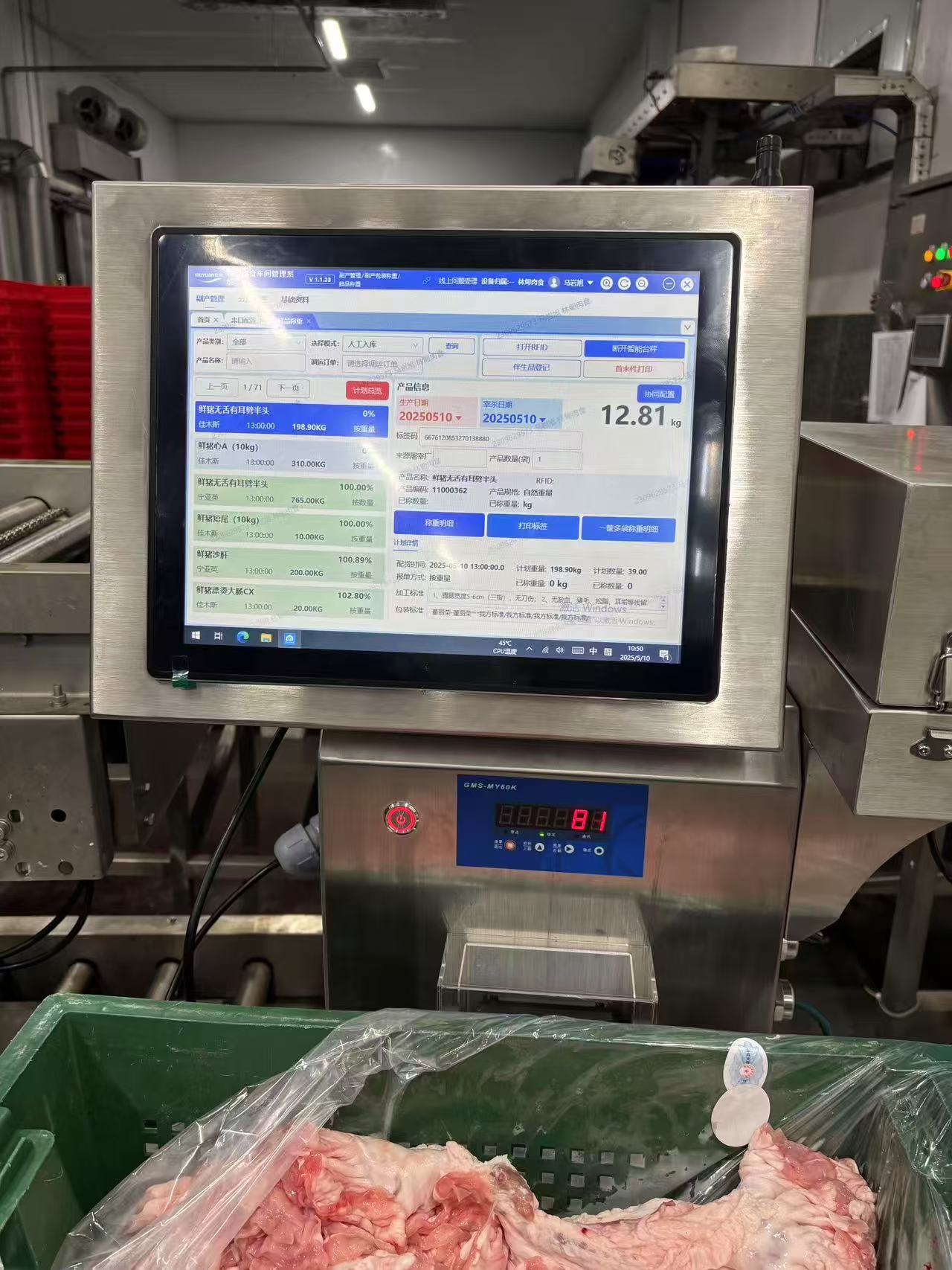

2. Platform Scales for Meat Products Weighing and Traceability

Post-slaughter, precision weighing plays a vital role in meats and bones classification, yield analysis, and traceability. General Measure provides rugged platform scales integrated with Muyuan's custom-built management systems to streamline this process.

Each cut of meat or bone is weighed using GM's high-accuracy platform scales, and the data is automatically transmitted to Muyuan's ERP system. This enables:

- Real-time recording and tracking of individual piece weights

- Batch and barcode linking for full traceability

- Accurate cost and inventory control across processing facilities

The seamless integration of weighing and digital records not only ensures food safety compliance but also supports refined product categorization and intelligent logistics.

|

3. Checkweighers for Final Product Inspection and Quality Control

In the packaging stage, Muyuan leverages General Measure checkweighers CW-30K to inspect the weight of meat and bone products before they leave the production line. These checkweighers provide real-time dynamic weighing that significantly enhances both quality control and packaging line efficiency.

Benefits of GM Checkweighers:

- Automated weight verification of each package

- Immediate rejection of under- or overweight items

- Reduced manual labor, improving ergonomics for workers

- Increased throughput and consistent product quality

- Integration with factory systems for live data acquisition and analytics

These systems form a crucial component of Muyuan's digital factory architecture, enabling real-time monitoring and data-driven decisions to optimize operations and ensure compliance with national and international standards.

Building the Foundation for Smart, Sustainable Pig Farming

Through continuous innovation and reliable performance, General Measure has become a trusted partner in Muyuan's journey toward intelligent farming. GM's comprehensive range of weighing products — from weighing indicators and load cells to platform scales and checkweighers — provide precision, stability, and easy integration with modern digital systems.

By enhancing automation, data visibility, and operational efficiency, General Measure is helping Muyuan to build a truly digital and intelligent livestock enterprise.